During a recent discovery session with a valued client one of their pain points involved the topic of automation and its impact on quality control. The following questions were high on their list of concerns: How can automated solutions enhance quality in centerless grinding? And, what role does data captured using automated systems play in quality assurance?

Typical quality issues of concern include dimensional inaccuracies such as out-of-tolerance diameter and roundness errors, surface finish imperfections like scratches or roughness, and internal stresses or subsurface damage that can compromise part integrity. Additionally, issues like inconsistent roundness, taper, and burn marks can affect the performance and lifespan of the finished components. Ensuring uniformity and adherence to tight tolerances is critical, as deviations can lead to assembly problems, increased reject rates, and costly rework, making rigorous quality control essential in centerless grinding operations.

Automated solutions significantly enhance quality control in centerless grinding by ensuring consistent precision, reducing human error, and increasing throughput; automated handling systems integrated with advanced sensors enable real-time monitoring which can not only classify material but can also detect inconsistencies and defects during production. The ability to immediately obtain and evaluate this data allows for quick adjustments, leading to tighter tolerances ensuring high-quality output while reducing waste.

Data from this immediate feedback plays a crucial role in quality assurance by providing actionable insights through real-time analytics and traceability, allowing operators to identify trends, pinpoint potential issues quickly, and optimize processes. Over time this performance data can inform continuous improvement efforts, helping to refine processes and maintain top-quality standards in the long run. By integrating automation with robust data analysis, manufacturers can achieve higher consistency, reduce scrap rates, and maintain stringent quality standards in centerless grinding operations.

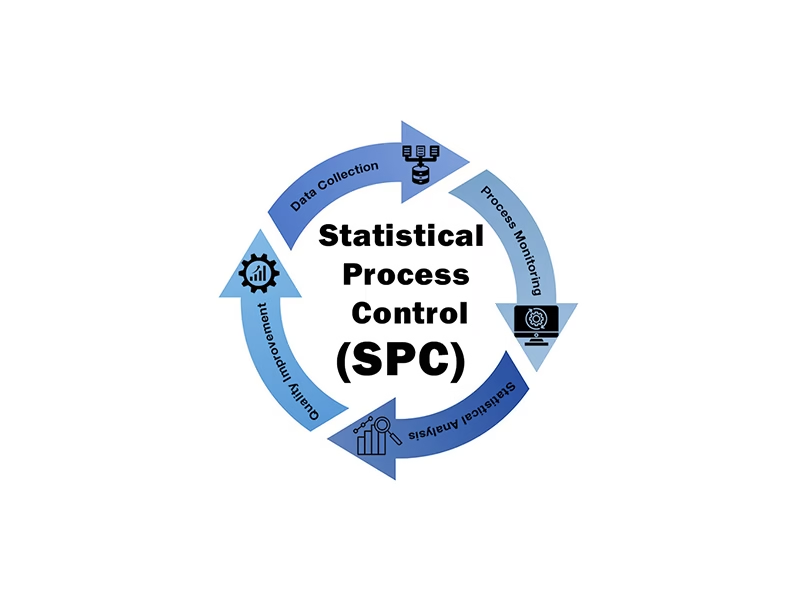

Data from control systems can be extrapolated to interact with SPC (Statistical Process Control), ERP (Enterprise Resource Planning) systems, or MES (Manufacturing Execution System) and can be leveraged in centerless grinding operations to optimize decision-making by providing real-time insights into process performance, material flow, and resource utilization. SPC data helps monitor and control grinding process quality, identifying variations and enabling corrective actions to maintain consistent product standards. ERP systems integrate supply chain, inventory, and production scheduling data, ensuring efficient resource allocation and demand forecasting. And, MES captures detailed operational data, such as machine status, cycle times, and operator activities, facilitating process tracking and continuous improvement. Combining these data sources allows managers to make informed decisions on process adjustments, maintenance scheduling, inventory management, and quality control, ultimately increasing efficiency, reducing waste, and enhancing product quality.

Utilizing SPC (Statistical Process Control), a software program that uses statistical analysis to determine when a product is going out of specification, is especially beneficial when consistent quality is a priority. Electro-Tech, Inc. can provide this software package in any one of three ways; as an integral part of our controls program, as a stand alone SPC, or we can provide the data to you so you can incorporate it into your existing ERP.