In the centerless grinding industry, maintaining optimal performance is crucial for efficiency and product quality. One common challenge that many manufacturers face is a slow dressing rate of the grinding wheel. “Dressing the wheel” means carefully reshaping and conditioning the grinding wheel’s surface to maintain its proper shape, surface finish, and cutting efficiency. This process involves removing any built-up debris, glaze, or irregularities on the wheel to ensure precise and consistent grinding of the workpiece, which is essential for achieving accurate dimensions and a smooth surface finish.

In centerless grinding, a slow dress rate can cause inconsistent surface finishes because the wheel may not be properly trued or dressed to maintain uniform cutting characteristics, leading to uneven material removal. Additionally, a slow dress rate can result in incomplete or uneven dressing of the grinding wheel, which accelerates wheel wear and reduces its cutting efficiency. This increased wheel wear necessitates more frequent dressing and wheel replacements, thereby raising operational costs. Furthermore, inconsistent finishes and increased wheel wear can cause deviations in part quality, leading to rework or scrap, which further elevates overall operational expenses. This article explores the causes of slow dress rates and offers automated solutions to mitigate or eliminate the problem.

Understanding the Causes of Slow Dress Rates

Several factors can contribute to a sluggish dress rate in centerless grinding. These include:

- Wheel Composition: The material composition and bond type of the grinding wheel can significantly influence its dressing characteristics. Softer bonds may wear down too quickly, while harder bonds might resist dressing, causing slower rates.

- Dressing Tool Setup: An incorrect setup of the dressing tool can hinder the dressing process. Issues could range from the wrong angle of contact to improper feed rates.

- Machine Parameters: Inconsistent machine settings, such as spindle speed and dress feed rate, can lead to ineffective dressing, thereby slowing down the process.

- Operator Skill: The experience and skill level of the operator play a significant role. Inexperienced operators may take longer to achieve the desired wheel profile, contributing to downtime.

Automation as a Solution

To address the issue of slow dress rates, automation can play a pivotal role. Here are several automation strategies that can enhance the dressing process:

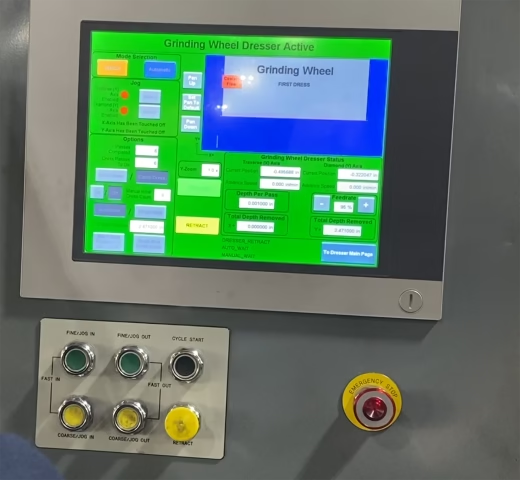

- Automatic Dressing Tools: Implement automated dressing systems that allow for precise and consistent dressing of grinding wheels. These systems can adjust parameters in real-time, optimizing the dressing speed and efficiency based on material and wheel conditions.

- Closed-Loop Control Systems: Integrating closed-loop control mechanisms can provide constant monitoring and adjustment of the dressing operation. Sensors can detect wheel wear and automatically adjust the dressing process, reducing manual interventions and ensuring optimal dressing rates.

- Robotic Automation: Deploying robots for dressing tasks can significantly speed up the operation. Robots can consistently perform complex dressing routines without fatigue, ensuring uniformity and reducing cycle times.

- Predictive Maintenance Tools: Utilize sensors and data analytics to gather real-time performance data about the grinding process. Predictive maintenance can prevent wheel and machine failings by identifying issues before they become problematic.

- Integration with Machine Learning: Machine learning algorithms can analyze past performance data to optimize dressing parameters and predict ideal conditions for different materials and wheel types, streamlining the dressing process.

Conclusion

A slow dressing rate in centerless grinding not only affects productivity but also quality and costs. By identifying the root causes of this issue and implementing automation solutions, manufacturers can vastly improve dressing efficiency, reduce downtime, and ultimately enhance their competitive edge. Embracing these technological advancements not only resolves the immediate issue but prepares the organization for a future where automated systems become increasingly critical in manufacturing excellence.